CONTINUOUS HAULAGE SYSTEM

Benefits to the Mine

The Industry Advantages for bulk material conveying technology.

Built to strict underground mine compliance, the Premron CHS will withstand extreme conditions whilst delivering a safer and more efficient material handling solution.

- Increased productivity for reduced costs

- Reduces delays and increases machine utilisation

- Development activities can now be done concurrently while you continue mining (NO delay)

- Enabler to improve roof bolting performance and hence provide further gains (23m/hr possible - unconstrained)

- Safer and environmentally friendly CHS

- The ability to negotiate tight turns at a small radius (Radius 6m x 90°- typical cut through)

- Averaging 7-10m/hr possible within a coal mine gate road with standard support density

- Reduce airborne dust - enclosed conveyor system

- Reduce manual handling hazards as CHS includes the face services on the machine (power, air, water & return lines)

- Ability to have resupply quicker with pods stored under the belt

- Ability to ‘Airodust’ concurrently with mining

- Ability for concurrent process tasks such as pipe and cable installation

- Reduced floor damage due to Premron roof mounted system

- Improved OH&S because no moving cars near workers

Eliminates wait on shuttle cars

The increased process rate can result in a significant advantage when completing a panel using the Premron CHS. The Premron can reduce operational delays in comparison to a shuttle car.

Removes delay of product transfer

Unlike a shuttle car, the miner loads into the Premron CHS and removes coal continuously at up to 500tph. The process rate will be steady throughout the entire pillar being cut as not reliant on wheel distance to the boot end.

Significant advantage on longwall float productivity rates

The Premron provides a significant advantage on cut and production rates in comparison to a shuttle car.

Productivity Comparison

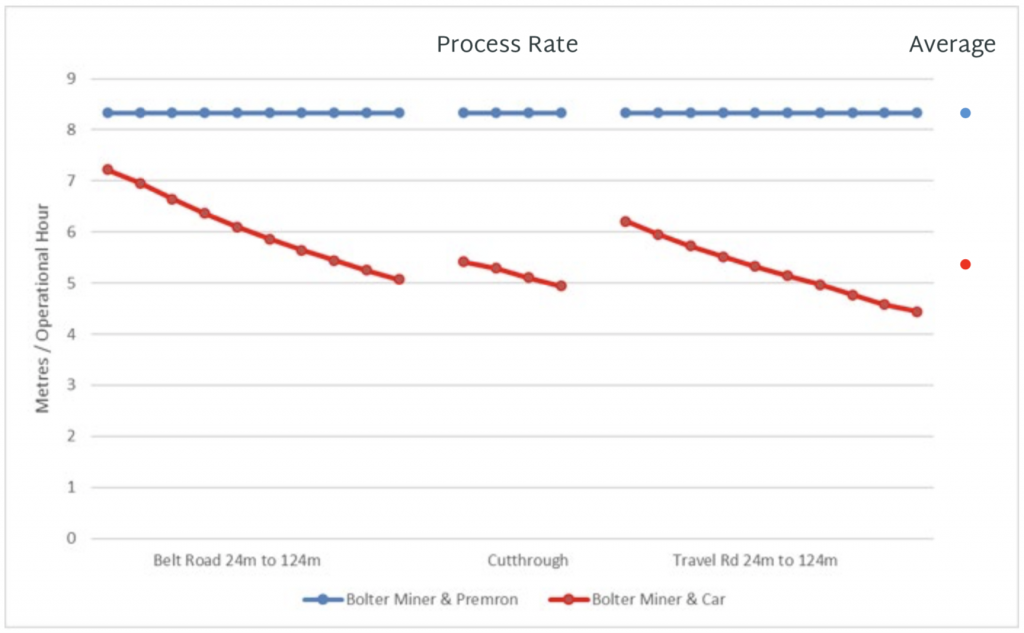

Data for a simulation demonstrating the difference in performance between a bolter miner loading into a Premron Continuous Haulage System (CHS) and a shuttle car is displayed in this graph, using a pure process without delays, and accounting for the interdependencies of cutting, loading and bolting processes and coal clearance.

As the face is mined further from the boot end of the fixed belt conveyor, the distance the shuttle car has to travel to discharge its load increases.

Consequently the process rate decreases as mining and bolting operations are delayed while waiting for the shuttle car to return for another load.

Premron Sizer Feeder is a mine compliant machine and offers complete optimisation.

With a hopper capacity of up to 10T, the machine sizes the product and feeds into the Premron CHS (nom-100mm), acting as a buffer between the Continuous Miner and the Premron CHS.